Industrial companies are always looking to improve their competitiveness in terms of productivity, profitability, flexibility, quality, and agility. Most of them will use Industry 4.0 technologies to solve this problem.

By investing more in the digital transformation of the factory, they want to achieve a high level of automation, better product quality tracking records, production scale-up, and sustainable development for the organizations.

But before they go any further in budgeting, they should take a step back and consider whether their factory’s IT and OT infrastructure can support a large number of additional new systems and equipment. This is an important consideration that most companies ignore.

At the heart of Industry 4.0 is the Industrial Internet of Things (IIoT), which enables factories to connect their machines, sensors, robots, and other devices to the Internet and each other.

One of the key challenges in implementing IIoT is choosing the right communication standard that can meet the demands of Industry 4.0. MQTT Sparkplug is a communication protocol designed specifically for IIoT. We will dive into MQTT Sparkplug and see what it brings to Industry 4.0.

What is MQTT Sparkplug?

MQTT Sparkplug is a messaging protocol built on top of MQTT, a widely used messaging protocol for IoT. It already has all the advantages of the MQTT protocol.

MQTT Sparkplug is designed specifically for IIoT and includes additional features that make it suitable for industrial applications. It is an open-source protocol that is widely adopted in the industry.

MQTT Sparkplug follows an MQTT publish-subscribe model, which means that devices and hosts can work independently and have real-time data communication to respond quickly to changes in the production process. It also defines a standardized message in binary format, which provides a consistent and efficient way of transmitting data between host systems and devices.

Evolution of MQTT Sparkplug

The Sparkplug protocol was initially released as version 1.0 by Cirrus Link Solutions in May 2016. It underwent subsequent updates, including version 2.1 in December 2016, which introduced “Payload B,” and version 2.2 in October 2019, when Cirrus Link rebranded the protocol for the Eclipse Foundation and added the trademark symbol.

These developments signify the ongoing refinement and growth of the Sparkplug protocol in the industrial automation and IIoT domain.

In the last year, the Sparkplug working group has announced a new protocol standard, v3.0, that brings significant advancements and formalization to the protocol for Industry 4.0.

General Benefits of MQTT Sparkplug for Industry 4.0

MQTT Sparkplug brings several benefits to IIoT systems in Industry 4.0:

- Scalability: It allows factories to add new devices and sensors as needed without impacting the performance of the system.

- Security: It provides a secure way of transmitting data between devices by using MQTT TLS encryption and authentication.

- Standardization: It ensures consistency and interoperability between devices and host systems from different manufacturers.

- Network efficiency: Its small packet size and efficient binary message format help to reduce the bandwidth usage of the system.

It also provides connectivity standards for integrating various clouds, systems, and devices.

- Integration with cloud platforms: MQTT Sparkplug allows factories to store and analyze data in the cloud, and enables advanced analytics and machine learning capabilities.

- Integration with legacy systems: With MQTT Sparkplug, legacy systems can be integrated easily through the Edge Node, enabling factories to leverage their existing infrastructure.

IT and OT Convergence

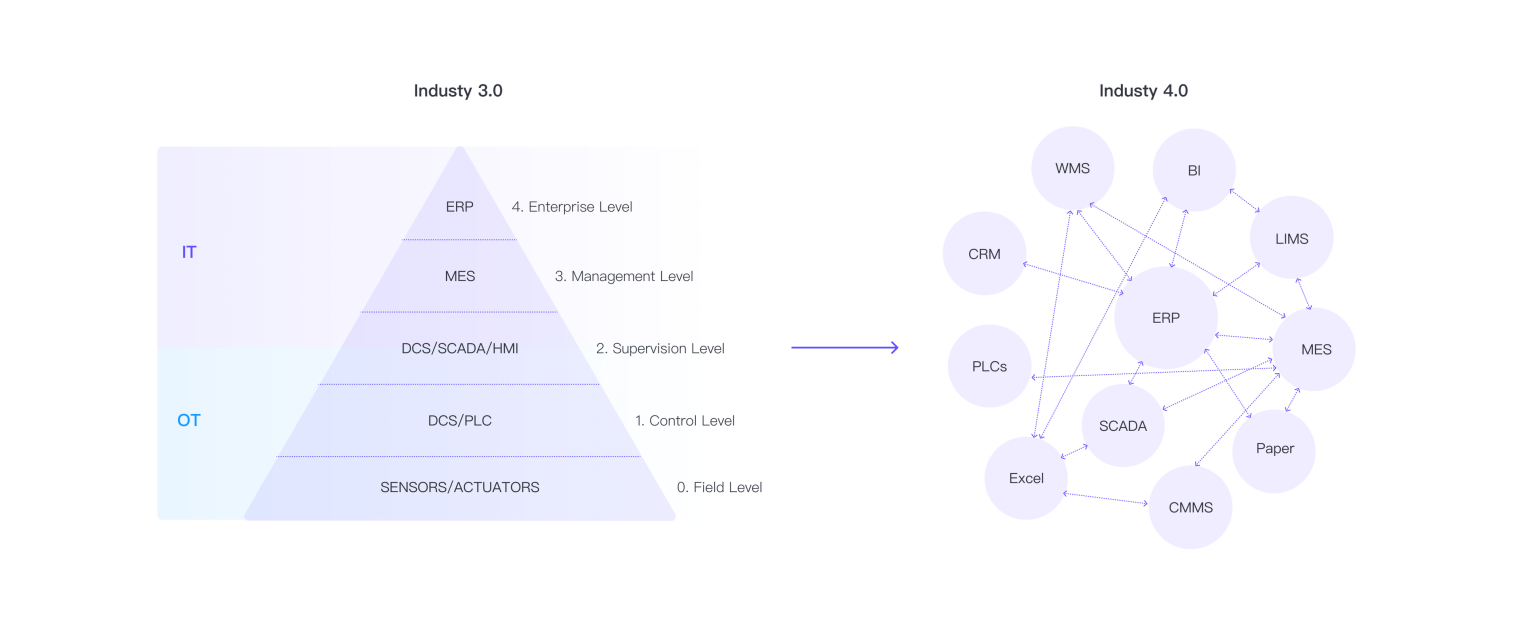

The majority of companies are still using Industry 3.0 technologies for production. In most Industry 3.0 systems, IT and OT systems have been separate and distinct, with IT systems focused on data processing and management and OT systems focused on controlling physical processes and machinery.

In the diagram of the automation pyramid shown, ERP and MES belong to IT systems, and SCADA, PLC, SENSORS, etc., are OT systems.

As required by Industry 4.0, more advanced technologies like cloud computing, big data, and robots would be added to the manufacturing infrastructure.

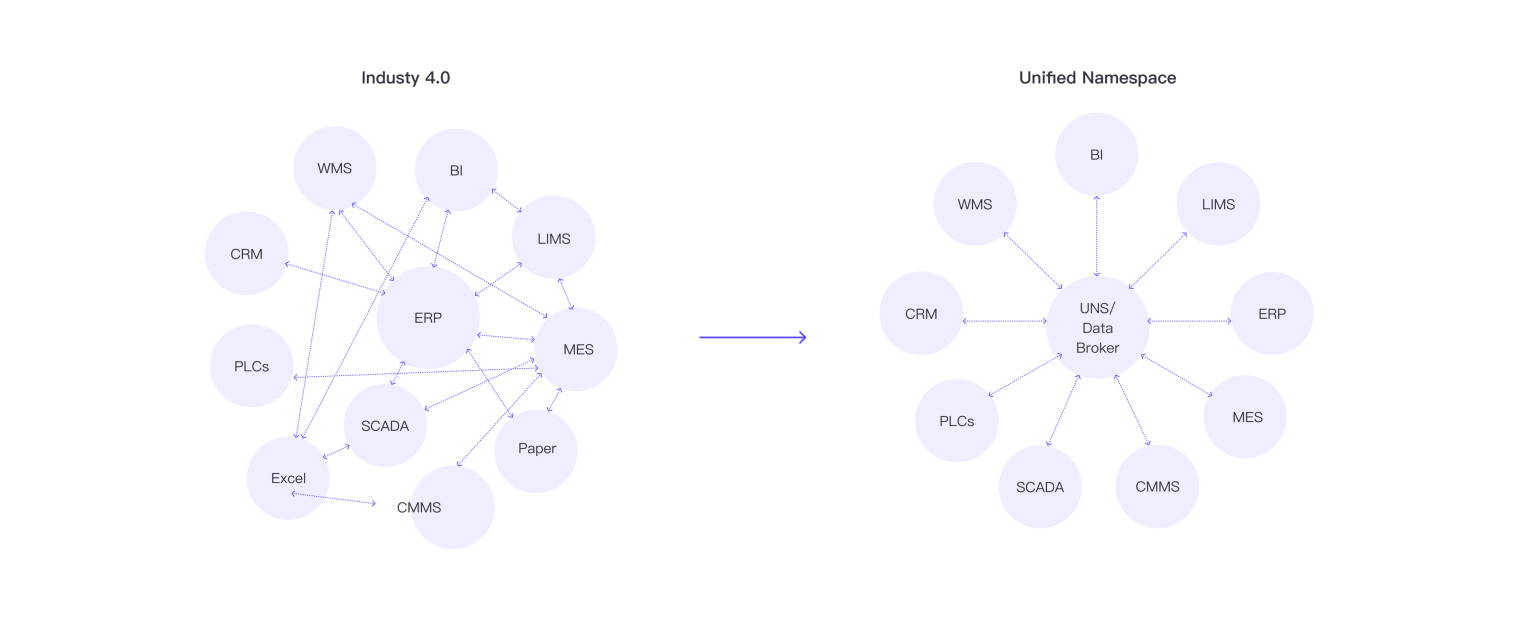

The more systems and devices to be added, the more complexity of the automation infrastructure. Ultimately, there are many tangled or unorganized communication channels between devices or systems.

Even though all systems use single protocols like OPC-UA to communicate with each other, the complex client-server connection network and routing mechanism still create challenges for the factory in terms of interoperability and data exchange.

To address these challenges, Sparkplug initiatives focus on developing standardized communication channels and protocols that can be used across different devices and systems. The development of standardized data models or ontologies that enable interoperability between different devices or subsystems.

By introducing a Sparkplug broker and a data ops gateway together as a central data hub for the IT and OT infrastructure, all host systems and devices are equally connected to this center data hub for data exchange.

Sparkplug host systems like ERP and MES and cloud platforms can directly consume the data message from PLC, devices, machines, and robots, realizing the IT and OT convergence.

Unified Namespace: Feature of Sparkplug to Simplify IIoT Management

One of the key features of Sparkplug is the use of a unified namespace. A namespace is a naming system used to identify and organize objects in a system.

In the context of Industry 4.0, there are typically multiple devices, sensors, and systems that need to communicate with each other. Each device or system may have its unique naming system or identifier, making it difficult to integrate and cohesively manage them.

The unified namespace enables a centralized management approach. With a unified namespace, administrators can easily monitor and manage all devices and systems in the network from a single location.

This can be particularly helpful in large-scale industrial environments where there may be hundreds or thousands of devices and systems to manage.

In addition, a unified namespace also facilitates the automation of system control and monitoring tasks. By providing a standardized way to identify and interact with devices and systems, Sparkplug can be used to automate tasks such as device configuration, software updates, and system diagnostics. This can help to reduce the workload of administrators and improve the overall efficiency of industrial operations.

A unified namespace also provides a standardized way to organize and structure data, allowing for contextualized and normalized data representation. With a unified namespace, any IT system can consume data from any OT system, and vice versa, without requiring extensive data mapping or translation.

Consumer applications like AI/ML, Historian, and SCADA can benefit from this standardized data structure data, improving data processing in terms of speed and data integrity.

The use of a unified namespace in Sparkplug simplifies the process of managing and monitoring industrial systems in Industry 4.0 environments.

By enabling centralized management, facilitating automation, and improving troubleshooting capabilities, a unified namespace helps to improve the overall efficiency and effectiveness of industrial operations.

Building an MQTT Sparkplug Solution

To implement an MQTT Sparkplug solution, we need two components: an MQTT server and an edge node.

An MQTT server is used as the central broker for handling the communication between devices and applications in an IIoT environment. The MQTT server is responsible for receiving messages from devices, forwarding them to the appropriate subscribers, and storing messages for later retrieval if necessary.

An edge node is a device or gateway that acts as an intermediary between devices and the MQTT broker. It can handle local data processing and aggregation, as well as buffering and forwarding data to the MQTT broker. Edge nodes are typically used in IIoT environments where numerous devices generate large amounts of data and where network bandwidth is limited.

In the context of MQTT Sparkplug, edge nodes are responsible for implementing the Sparkplug specification, which includes handling the registration of devices, encoding and decoding data using the Sparkplug payload format, and organizing data using the Sparkplug topic namespace format.

The edge node communicates with the MQTT server using the MQTT protocol, and it may also run additional software to perform local analytics or processing on the data.

By using a unified namespace, devices and systems can easily discover and communicate with each other, regardless of their naming systems. This makes it much easier to integrate and manage complex systems in Industry 4.0 environments and helps to ensure that data is accurately and consistently shared across the network.

MQTT Sparkplug vs. OPC UA

MQTT Sparkplug and OPC UA are both prominent communication protocols in the industrial IoT field.

MQTT Sparkplug is based on the MQTT protocol, which is a lightweight publish/subscribe messaging protocol. In contrast, OPC UA is a more comprehensive and complex protocol that encompasses both communication and information modeling aspects.

The scalable and efficient design of Sparkplug makes it suitable for resource-constrained devices and networks with limited bandwidth. OPC UA is more resource-intensive and is often utilized in systems where higher data throughput or complex interactions are required.

A more comprehensive comparison between these two protocols can be found in A Comparison of IIoT Protocols: MQTT Sparkplug vs. OPC-UA

Benefits for IIoT

In conclusion, MQTT Sparkplug is a powerful and efficient protocol that brings numerous benefits to the world of IIoT. Its efficient data transmission and built-in mechanisms for device discovery and data modeling make it an ideal choice for connecting and managing large-scale industrial networks.

By leveraging MQTT Sparkplug, businesses can unlock real-time data insights, improve operational efficiency, and drive innovation in their industrial processes.

As IIoT continues to grow and evolve, MQTT Sparkplug will undoubtedly play a crucial role in shaping the future of industrial connectivity, enabling smarter, more connected, and more efficient industrial systems.

Latest IoT News

Latest IoT News